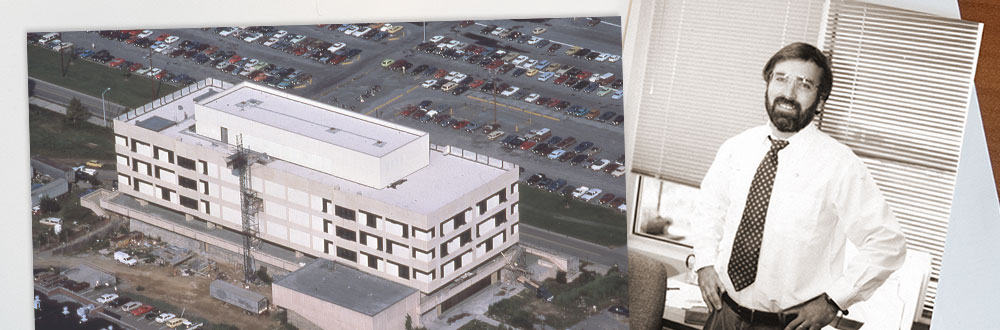

VPT’s headquarters is located in the Virginia Tech Corporate Research Center in Blacksburg, Virginia.

Inspiration

VPT, Inc.

The world’s leading supplier of high-reliability DC-DC power conversion products and custom engineering services for avionics, military, space, and industrial applications.

Employs: 200 direct employees + 250 at the Taiwan manufacturing facility

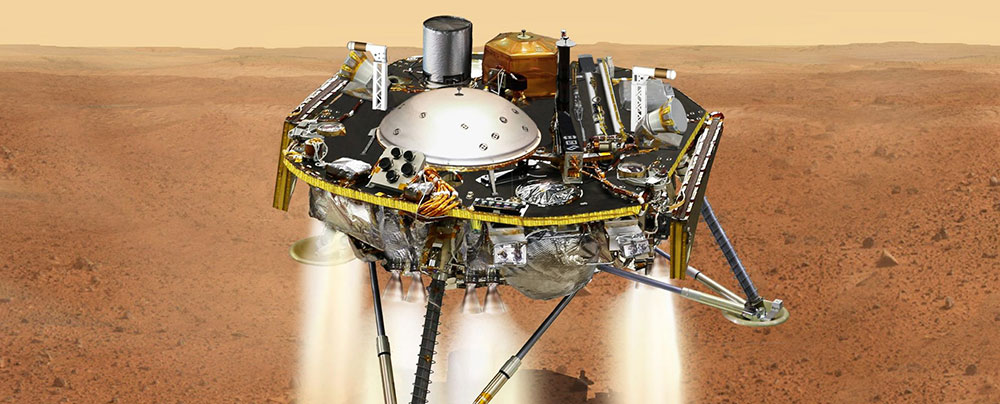

VPT is a local company with international presence — and interplanetary reach.

“Our products have been to Mercury, Venus Mars, the moon, and even Pluto,” says CEO Dan Sable. “We’ll get to them all eventually.”

VPT’s high-reliability DC-DC power converters are used in everything from GPS satellites and the International Space Station to submarines, helicopters, and tanks.

“You’d be hard-pressed to find a major military or commercial avionic program that we don’t have some product on,” says VPT President John Hodock.

Born from a hallway conversation

Today, VPT employs around 200 people in Blacksburg, Seattle and Boston, and runs manufacturing facilities in Taiwan. In 2009, VPT was acquired by Heico Corporation, a multinational aerospace company headquartered in Florida. VPT is one of the New River Valley’s most successful companies.

But the idea for this company was sparked 26 years ago, the result of a chance meeting and casual conversation… in a hallway—the hallway on the first floor of Virginia Tech’s Whittemore Hall, to be precise.

Sable, who had a background in the space industry, had finished his Ph.D. in Virginia Tech’s electrical and computer engineering department. His thesis advisor was Fred Lee, a world-renowned power electronics expert who founded and directed the Center for Power Electronics Systems (CPES).

“Fred stopped me in the hallway one day and asked if I had ever thought about starting a company,” says Sable. “So, we started VPT kind of on a whim, the result of that hallway conversation.”

Powering up

Virginia Power Technologies Inc. (now known simply as VPT Inc.) began as a contract research and development company. They operated out of a one-room office in the Virginia Tech Corporate Research Center (VTCRC), which “provided a welcoming and nurturing environment for startup companies,” says Sable. “The university provided a talent pool, and I think those things together have made Blacksburg a good choice for us.”

After securing a few contracts and a patent for a laptop power supply, VPT was approached by a Taiwanese company, Delta Electronics, with a proposal to strike out on a joint venture. A simple one-page contract put them on a path to designing and manufacturing standard power converters for space, avionics and military applications.

“That one-page agreement has stood the test of time,” says Sable. “We now have about 250 people in Taiwan that are dedicated to our operation.”

Growing up

As the company grew, it expanded its footprint. In 1998, it moved to bigger space in Blacksburg’s Industrial Park. In 2012 it returned to the CRC, much larger and with a new parent company—Heico Corporation.

“They own pretty much all of VPT,” says Sable. But they didn’t want to change the successful trajectory VPT was following, he adds. “The first thing they said to me was just keep doing what you’re doing and let us know if we can help.”

In addition to its Taiwanese facility with 250 employees and Blacksburg R&D headquarters and shipping department with 65-70 people, VPT has a marketing and sales department in Seattle with 12 full-time employees. The sales department manages a global network of hundreds of representatives and distributors.

VPT has also expanded vertically and owns subsidiary companies in the Boston area, including a radiation test facility, VPT Rad, and a high-reliability semiconductor components manufacturer, VPT Components.

Long-term reliability

VPT’s central focus is reliability. They start working with the latest technologies early, making sure that they are reliable before integrating them. This has kept VPT on the leading edge of “a technology that never changes,” according to Hodock. “I say that jokingly, but we are pushing the envelope to the leading edge of an industry that changes very slowly,” says Hodock. “It’s not the commercial world — the very nature of space and defense is conservative and prioritizes reliability.”

When a component is designed, tested and approved into a high-reliability program, it must function perfectly for a very long time, says Sable. Commercial aircraft, for instance, aren’t being redesigned every few months, as is the case in many earth-bound industries, like telephony. Once engineers qualify an aircraft, they’re hesitant to risk what they know to be safe and reliable for a cheaper or newer product.

The production cycle for VPT’s targeted industries is on the scale of decades, according to Hodock. “Many technologists talk about obsolescence in three months. Our obsolescence is 25-30 years.”

When reliability is the first requirement, and system life cycle is measured in decades, designing, building and integrating new technology into existing systems requires creativity and advance planning. VPT engineers continue to develop the next generation of power converters, then run them through rigorous testing.

One opportunity for VPT to implement new technology is when systems undergo routine electrical upgrades. They are currently exploring ways to incorporate Gallium Nitride (GaN), which could increase converter efficiency and radiation tolerance.

But VPT’s tried-and-true selling points lie in high quality, customer service and reliability.

Establishing reliability

To sell parts for high-reliability applications, every component must be qualified, which requires testing for every future circumstance and harsh environment.

“By the very nature of the end-use applications, these parts cannot fail,” says Hodock. “If your component is up in a satellite or on a missile, nobody is going to go up there and fix it.”

And if one fails, the whole batch is shipped back for repair at the company’s expense—a situation which VPT faced as a young company.

How did they recover?

“We just did the right thing,” says Sable. “We went through everything to find the root cause of the problem. Then it’s about new material, new processes for manufacturing and doing it again.”

This process was complicated by the fact that VPT relies on an extensive supply chain. “Our parts are made of hundreds of smaller components,” says Hodock. “But we have found that treating our vendors and supply chain as partners instead of as expenses has really worked for us.”

This sentiment applies to VPT’s employees and associates as well.

“We have the lowest turnover rates of any company I’ve been associated with,” says Hodock. “Voluntary turnover is almost zero, here and in Taiwan, and it’s been that way for 20 years.”

Here, Hodock and Sable also credit their long-term presence in the region, as well as the region itself, for low turnover rates.

Virginia Tech graduates often come back to Blacksburg, says Sable, who is an adjunct professor in the Virginia Tech’s electrical and computer engineering department. Eight of his former students are now VPT engineers, and about 80% of Blacksburg-based VPT employees have some association with Virginia Tech.

“It’s a great place to live. It may be a little bit harder to recruit them because of where we are, but once we get them, it’s easier to keep them,” explains Hodock. “We don’t have a lot of the problems of bigger cities, there’s great weather and outdoor activities. The NRV has a lot to offer in that regard.”

With high-quality, high-reliability products and a happy workforce, VPT’s trajectory remains true to a growing, interplanetary company firmly rooted in the New River Valley.