Virginia Tech Researchers Develop Novel Latex Rubber 3D Printing Material

An interdisciplinary team of researchers led by Virginia Tech University (VTU’s) Macromolecules Innovation Institute (MII) have collaborated with Michelin North America to create a novel 3D printed latex rubber material.

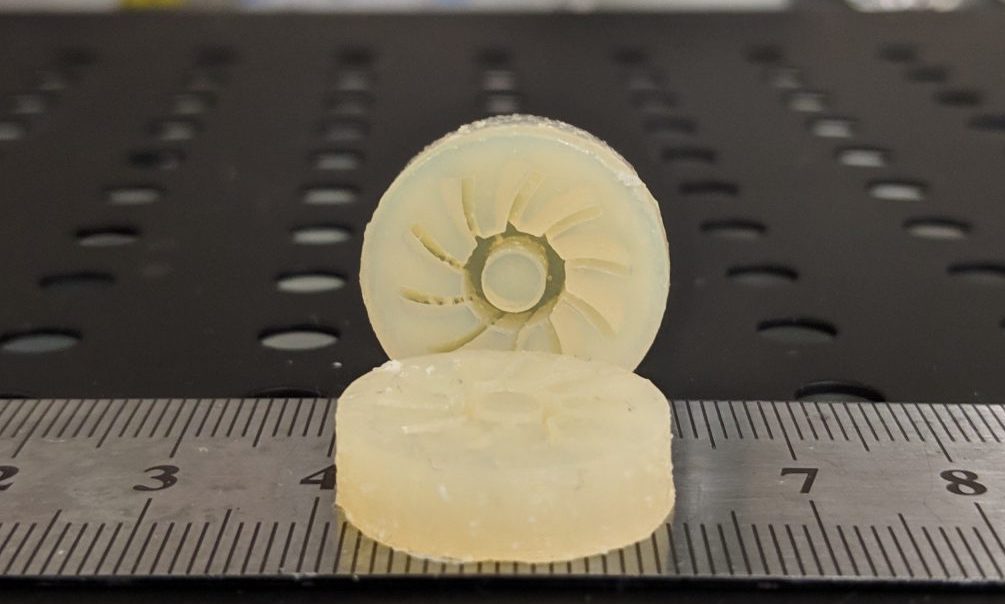

By adding photoinitiators and other compounds to a latex liquid mixture, the team were able to integrate a supporting scaffold into its polymerization 3D printing process. This new technique yielded a novel latex material exhibiting improved cohesion, which could lead to its future application in areas such as soft robotics, medical devices, and shock absorbers.

“When I was a graduate student working on this technology, we were excited to get unique performance from the shapes we could create, but the underlying assumption was we had to make do with very poor materials,” said Christopher Williams, the L.S. Randolph Professor of mechanical engineering at MII. “What’s been so exciting about this discovery, is being able to push the boundary of what we assumed was the limit of a printed material’s performance.”

Vat photo-polymerization, also known as stereolithography 3D printing, enables the fabrication of precise and complex geometries, objects printed in this way usually comprise highly crosslinked, polymeric networks. With some materials parts can be brittle. Moreover, because successful photocuring demands that these crosslinks be present to maintain feature fidelity, the resulting parts often feature limited elasticity.

To learn more, check out the whole article below.